CajoSmart™ embedded software is designed for high-speed and time-critical manufacturing processes. This revolutionary solution provides first-class laser markings in hectic manufacturing environments. It is an embedded onboard control system that enables laser marking without a PC on the production floor. The typical application is a high-speed 24/7 production line where markings are done on the fly. Marking content can be fetched from other systems or entered manually from a touchscreen user interface (HMI option). After the marking sequence is initialized the software handles the marking process from start to finish.

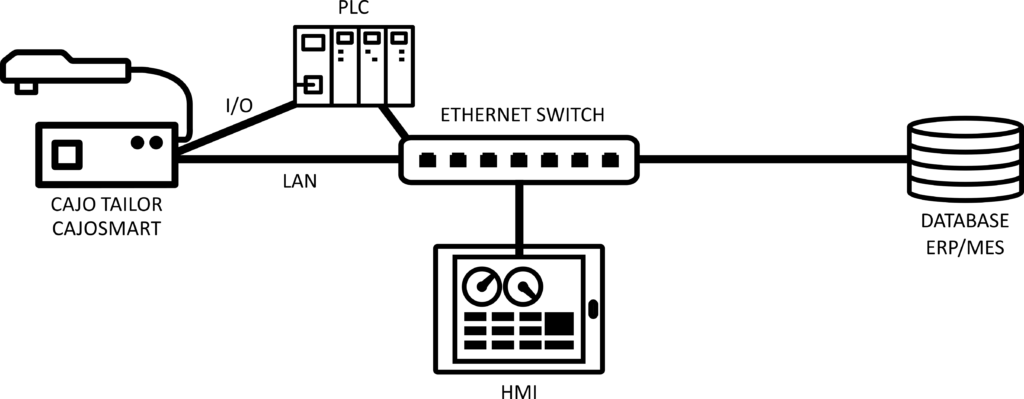

The Cajo laser marking system and embedded CajoSmart™ software integrate seamlessly with other production systems on a manufacturing floor. CajoSmart™ can be run without a user interface by executing commands through a local area network (LAN). This allows, for instance, another automation system (PLC, robot, MES, etc.) to control and monitor the operation of the Cajo laser marking system. The content of the marking can be changed using the same interface.