Solutions for EV Battery Manufacturing Industry

Solutions for EV Battery Manufacturing Industry

EV battery manufacturing is rapidly expanding, making traceability critical for product quality and end-of-life recycling. Cajo’s flexible laser marking solutions enable high-speed, permanent coding on battery foils, ensuring full compliance and sustainability throughout the entire product lifecycle.

Traceability important factor in lithium-ion battery markets

In the past few years, the development and production of electric vehicles (EVs) has expanded remarkably. Almost every week we can read from the news that new “gigafactories” are built or are planned to build in the near future.

EVs are commonly using rechargeable lithium-ion batteries as a clean power source. After serving as the power source for EVs, battery recycling will become a major challenge in the future. Therefore product identification and traceability need to be carefully considered from the early stages of production.

Readable and permanent markings enable product traceability internally and externally. This ensures traceability throughout the supply chain and the whole product life cycle reducing material waste.

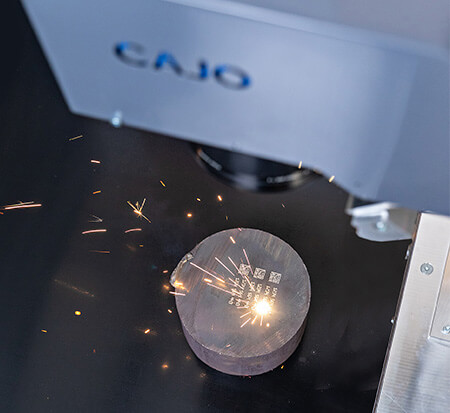

Cajo’s flexible marking solutions enable the smooth installation of laser marking systems on both new battery production lines under construction and pre-existing EV lines. Any necessary retrofitting is completed accurately and efficiently by our skilled technical experts according to the customer’s needs.

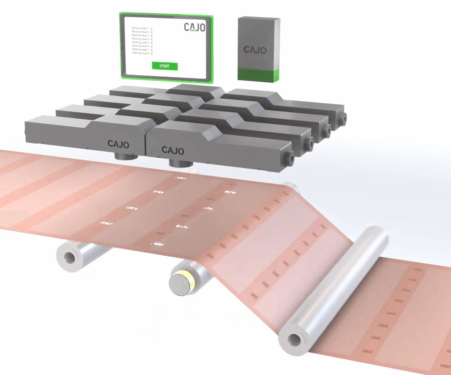

Turnkey solution for traceability coding of electric vehicle battery foils

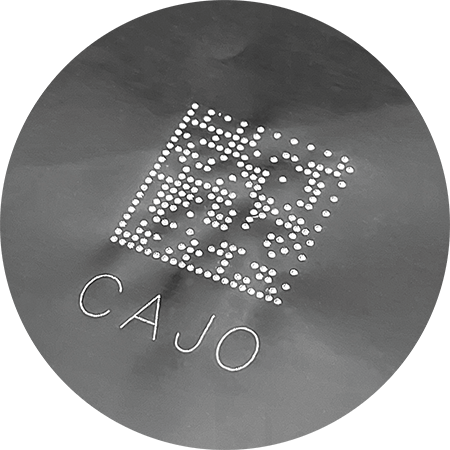

Cajo Hercules for Foil Marking™ is a turnkey, laser class 1 solution for traceability coding of electric vehicle battery foils.

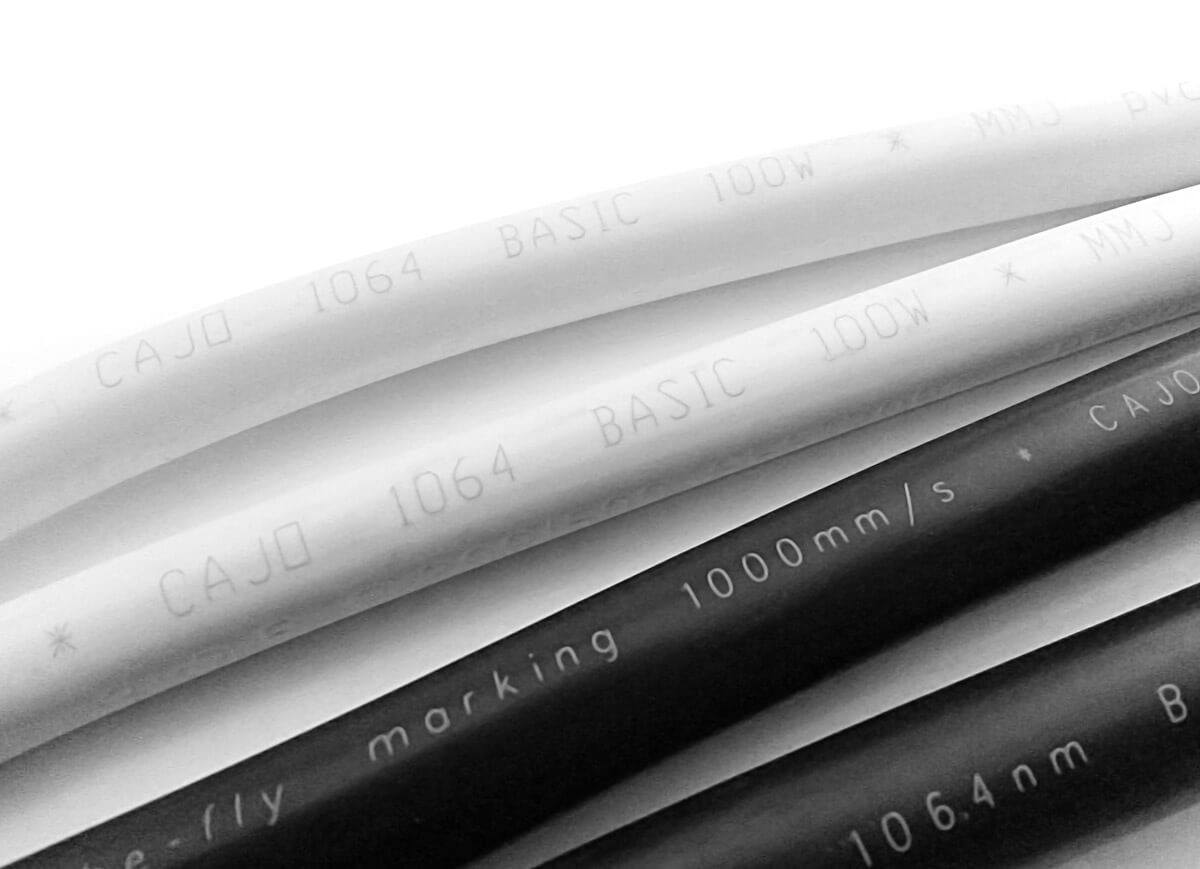

The marking solution enables high-speed on-the-fly marking of 2D codes while delivering optimum marking results for coated and uncoated aluminium and copper foils. The amount of Cajo Tailor™ units can be changed depending on customer needs. Each Cajo Tailor™ unit can mark over 20 unique data matrix codes per second.

Solution highlights

- 2D codes on aluminium and copper foils

- For coated and uncoated aluminium and copper foils

- Typical line speed over 80m/minute

- Each Cajo Tailor™ unit can mark over 20 unique data matrix codes per second

- Integration with customer MES

- Encoder for speed measurement

- User-friendly HMI panel

Eu compliant ev battery markings with cajo laser

The European Union has released extensive legislative proposals to create a legal framework for battery production’s sustainability, traceability and circularity throughout a product’s life cycle. The draft is expected to come into effect in 2022.

Cajo Technologies is an expert in laser marking that can meet strict international standards with sustainable solutions for full traceability. Read more about the EU’s extensive plans for the Battery Industry and how Cajo can help battery manufacturers keep up with the progress by improving yield and minimizing scrap.

More solutions by industry

Trusted by leading companies

Discover some of the organizations that rely on our expertise.